🙃 We Goofed!

Last week we sent out a form asking for compensation data.

A ton of you clicked the link !!!!!

Unfortunately, I FORGOT TO PUBLISH the form as public until a couple hours after the newsletter went live. As such, we did not receive enough responses. I am once again asking you to submit compensation data for the good of the community. If you’re not convinced yet, read the spiel from last week:

It’s pretty rare that we ask anything of our readers (either on the website or the newsletter). Our northstar has always been to make technical interviews less daunting through simple, first principle explanations of common concepts asked in interviews, or topical deep dives we think our viewers will find interesting. One dream for the site that we haven’t delivered on yet is more information on compensation! This is something that changes YoY and with the job market (especially true of FTE compensation). As such, in an effort to put together some pay transparency and expectations content for you, I would be forever grateful if you could fill out this form. We will anonymize any submissions (of course), and aggregate data so that it cannot be traced back to you. If we do not get enough submissions to anonymize the data effectively, no content on this topic will be published from HWH. Knowledge is power and in this economy, it can only benefit you to know how much your peers make and when is the right time to ask for a raise. Whether you’ve only interned or you’re a senior engineer, please help us help you by filling out this form.

⚙️ Mechanical Engineering Resources:

We have put a dozen guides for mechanical engineering students and early professionals on our website

50 Hardware Startups who have raised less than $50 million (perfect internship targets)

How to handle The Behavioral Interview

What it take to be The 10X Intern

💼 Jobs & Internships

Freshmen - Check out our 4-Year Plan for how to get internships at startups!

Sophomores - Apply To These Positions

Charm Mechanical Engineering Intern

Amphenol Mechanical Engineering Intern

SRC Mechanical Engineering Intern

Juniors - Full Send Longshots!

Locus Robotics Manufacturing Engineering Intern

ASML Manufacturing Engineering Intern

Vitamix Manufacturing Engineering Intern

Seniors & Graduates - It’s Go (Full) Time!

Super Tough:

Intellectual Ventures Mechanical Design Engineer

SpaceX Life Support Engineer

Astranis Mechanical Engineer - Associates Program

More Reasonable:

Hippo Harvest Manufacturing and Equipment Engineer

Callaway Golf Ball Development Engineer

Nightwing Mechanical Engineer

Not seeing what you are looking for? Check out our Job Board for more MechE positions!

👶 Meme Of The Week

🙋♂️ Interview Practice Question of the Week

It’s your first day at a very boring large company. You spend the day doing compliance and onboarding training. Bored out of your mind, you realize that all the office chairs in the office have 5 legs. This gets you thinking . . .

Why do most office chairs have 5 legs instead of 3 or 4? Or 6

or 7 for that matter?

What factors went into this decision, and why was 5 so

universally chosen?

Try to include quantitative analysis if possible.

✅ The Answer

When you first approach this problem, you should start by listing the major factors which could go into deciding how many legs should go onto an office chair. Just a few are discussed here:

Cost

As an engineer (not a scientist), cost should be one of the first things that comes to mind. In this case, it would come from tooling, material expense, and shipping weight/footprint primarily. All of these cost factors can reasonably be associated with the number of legs. More chair legs equate to higher weight, more material, and pricier tooling (though tooling can probably be assumed to be amortized to ~0 in this case).

When considering cost, there is also the matter that much of the cost of the chair (or somewhat associatively, weight) is fixed. No matter how many legs the chair has, there still must be a portion for someone to sit in, and a center post to allow vertical adjustment. As such, it is not accurate to say that the cost of an 8-legged chair is twice that of a 4-legged one. Depending on the chair, the cost of the legs alone is likely to change in proportion to the total cost. As an example, for simplicity of calculations, one could assume the chair to have a fixed cost of 5 (to be normalized later) plus the number of chair legs.

Footprint/Area

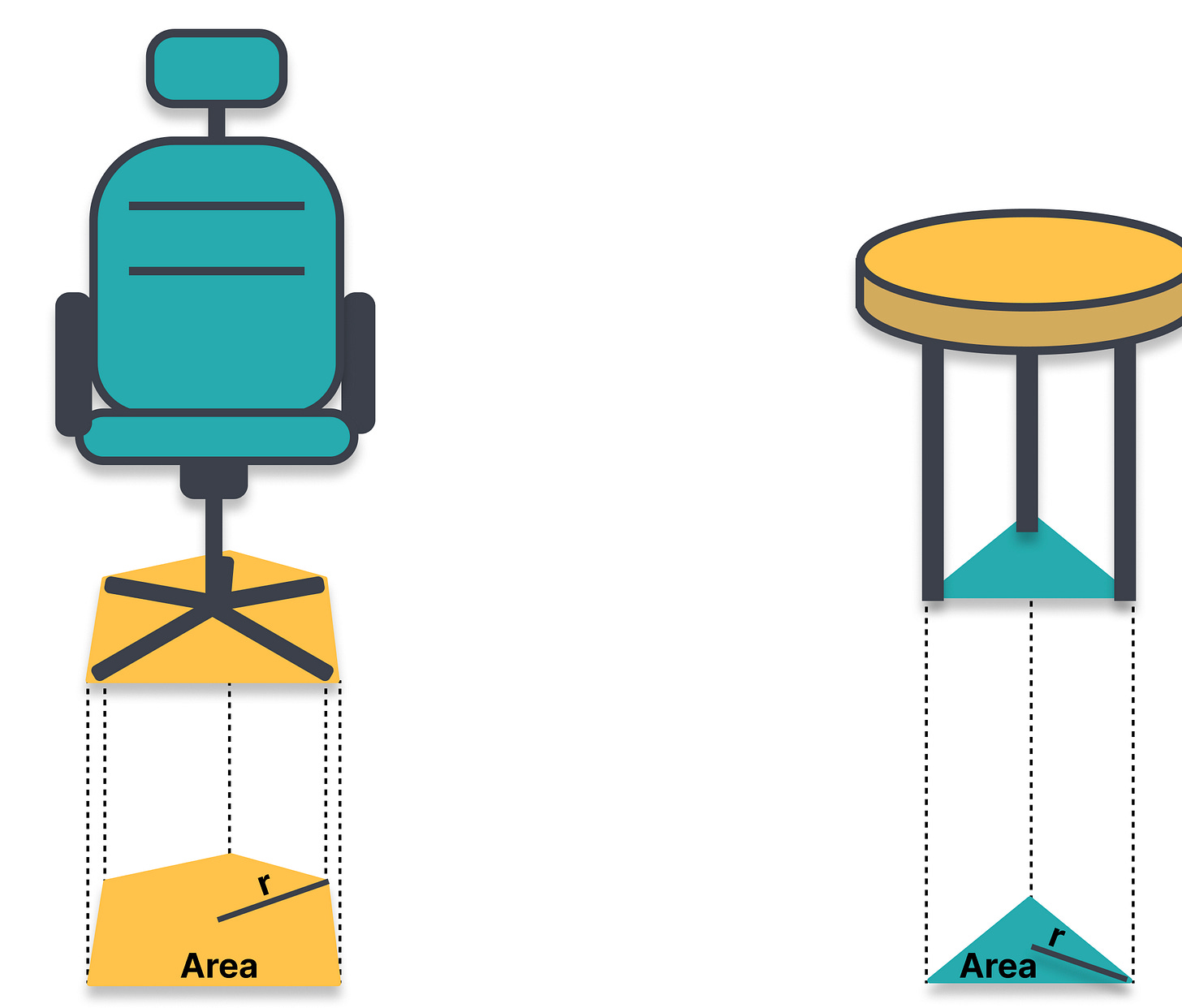

The next category is footprint/area for a given leg length. As leg length increases, the sitter can lean further without causing the chair to tip over (in other words, the user’s center of gravity has a larger functional bounding radius). This area can thusly be used as one metric to judge consumer value received as a function of the number of legs. Normalized areas of 3-7 legged chairs can be found in the summary table.

Minimum Tip Over Distance

Another metric of consumer value could be minimum tip distance. Closely related to our last metric, the minimum tip distance is the smallest distance from the center to a polygon edge (in other words, the minimum distance the user must lean to cause the chair to tip over). This acts as another realistic use case, as the base of an office chair is frequently prone to rotation, and leaning in a given direction for one rotation vs. another results in drastically different tip distances, particularly for fewer legged chairs.

So you’ve brainstormed a bunch of different factors.

What happens when there are manufacturing defects?

How about minimum wobble distance?

In an ideal world, perhaps all chair legs are the same length and lie in the same plane. However, we so rarely find that reality matches our ideal scenario. Were one leg to be slightly out of tolerance, whether it be too long, off-angle, or too tall, this would result in a wobble.

If you have ever gone to eat at a local pizzeria and found that one of the tables shifts substantially when you put your elbows on it, you are familiar with the wobble I am describing. That wobble can be characterized by drawing lines between all vertices and finding the minimum length from the center to intersect with one of those lines. Herein lies the true strength of the 3 legged stool (unwobbleable).

Here’s a graphic I put together visualizing the performance metrics we’ve mentioned thus far. By normalizing (dividing each column by the worst score in the column), we are able to generate a plot which should theoretically show the visual tradeoffs between the different legged designs. The area encircled by each line would then by roughly equivalent to “consumer benefit.” It can be immediately seen that 4 and 6 legged chairs do not perform favorably based on our metrics since they are virtually guaranteed to wobble right across the center. 3 performs amazing for wobble distance, but rather poorly by our other two metrics. Then we are left with 5 and 7 legged chairs. To compare between the two, it really comes down to 2 things: cost and optimization. The cost numbers shown in this table are very low fidelity. An optimization function would do a far better job of conveying the winner than the below graphic. For example, depending on the manufacturer, perhaps cost is 5x as important as area.

Regardless, you can see below that the 5 legged chair is a bit of a chair-of-all-trades in that the marginal benefit in performance per added leg after 5 is relatively low, yet a chair of 5 legs still performs well in wobble and cost. Hope you learned something!